Why 3D Printers Can’t Read STL Files Directly – and Why GCODE Exists

If you’ve ever downloaded a 3D model and tried to send it straight to a 3D printer, you’ve probably hit a wall pretty quickly. The file looks perfect on screen, the geometry checks out, but the printer itself has no idea what to do with it. This usually happens with STL files – the most common format for sharing 3D models.

At first glance, this feels counterintuitive. STL files define the shape of an object in precise detail, so why can’t a 3D printer just “print the model”? The answer lies in a fundamental difference between what a model is and what a machine needs in order to act.

STL describes shape, not behavior

An STL file is essentially a static description of geometry. It breaks a 3D object down into thousands (sometimes millions) of tiny triangles that together define the surface of the model. There is no information about layers, printing speed, temperatures, or even the size of the printer’s build volume. STL doesn’t say how to create the object – only what it looks like.

For humans and software, that’s perfectly fine. CAD tools, 3D viewers, and modeling apps can easily interpret this geometry. A 3D printer, however, is not a design tool. It’s a machine that moves motors, pushes filament, controls heaters, and follows very specific instructions in real time.

That’s where STL reaches its limit.

GCODE is a language machines understand

GCODE exists because machines need instructions, not shapes. Instead of triangles and surfaces, GCODE is made up of commands like “move here,” “extrude this much material,” “heat the nozzle to this temperature,” and “wait until the bed is ready.”

Every single layer of a print is broken down into motion paths, speeds, and timing. The printer follows these instructions line by line, much like a CNC machine or industrial robot would. Without GCODE, a printer simply doesn’t know where to move, when to extrude, or how fast to operate.

In other words, STL answers what the object is, while GCODE answers how to make it.

The missing step: translation, not conversion

When people talk about “converting STL to GCODE,” what’s really happening is interpretation. Software takes the raw geometry and translates it into physical actions that make sense for a specific printer setup.

This step is often called slicing, because the model is divided into horizontal layers that the printer can build one by one. During this process, decisions are made that an STL file simply doesn’t contain: layer height, infill density, support structures, print speed, retraction behavior, and more.

Because these settings depend on the printer, material, and even the user’s priorities (speed vs. quality, strength vs. weight), there is no single universal GCODE file for an STL model. The same STL can produce very different GCODE outputs depending on how it’s processed.

Why printers can’t do this themselves

It might seem logical for a 3D printer to handle this translation internally, but in practice, that would make printers far more complex, expensive, and difficult to update. Slicing software evolves quickly, adding new algorithms, support strategies, and optimizations. Offloading this work to external tools keeps printers simpler and more reliable.

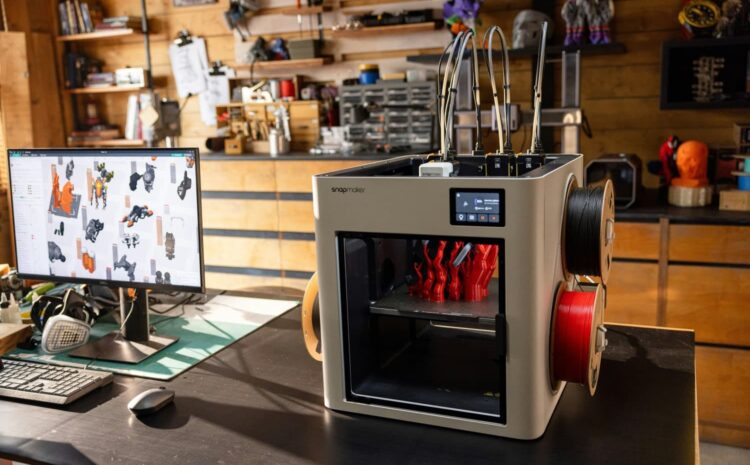

That’s why most workflows rely on dedicated software – either installed locally or available online – to handle STL to GCODE conversion before anything is sent to the printer.

Offline slicers vs. online converters

Traditional desktop slicers like Cura, PrusaSlicer, or Simplify3D give users deep control over every aspect of the print. They’re powerful, flexible, and ideal for advanced users or production environments where fine-tuning matters.

At the same time, online tools have become increasingly popular, especially for quick tasks, previews, or situations where installing software isn’t practical. Browser-based converters allow users to upload an STL file and get a ready-to-use GCODE file without worrying about operating systems, updates, or hardware limitations.

Online STL to GCODE converters like AnyConv fill this niche well. They’re particularly useful when you need a fast, straightforward conversion or when you’re working across multiple devices. While they may not replace full-featured slicers for every scenario, they lower the entry barrier and make 3D printing more accessible.

The real takeaway

The reason a 3D printer can’t read STL files directly isn’t a limitation – it’s a design choice. STL files are about geometry. Printers operate on motion and control. GCODE bridges that gap by turning abstract shapes into precise, physical actions.

Once you understand this separation, the STL-to-GCODE step stops feeling like an inconvenience and starts making sense as a necessary translation layer. It’s the moment where a digital model becomes something a machine can actually build – one line of code, one layer at a time.